As part of a partnership with the French National Center for Scientific Research (CNRS), Stellantis and Saft have created what they describe as a “revolutionary” prototype battery. The new design integrates charger and inverter functions into the battery, making the powertrain more efficient, more reliable, and less costly.

The design still works with lithium-ion cell chemistry, but integrates more functions into the battery itself. The result of more than four years of research, the Intelligent Battery Integrated System (IBIS) is finally ready to be shown to the world.

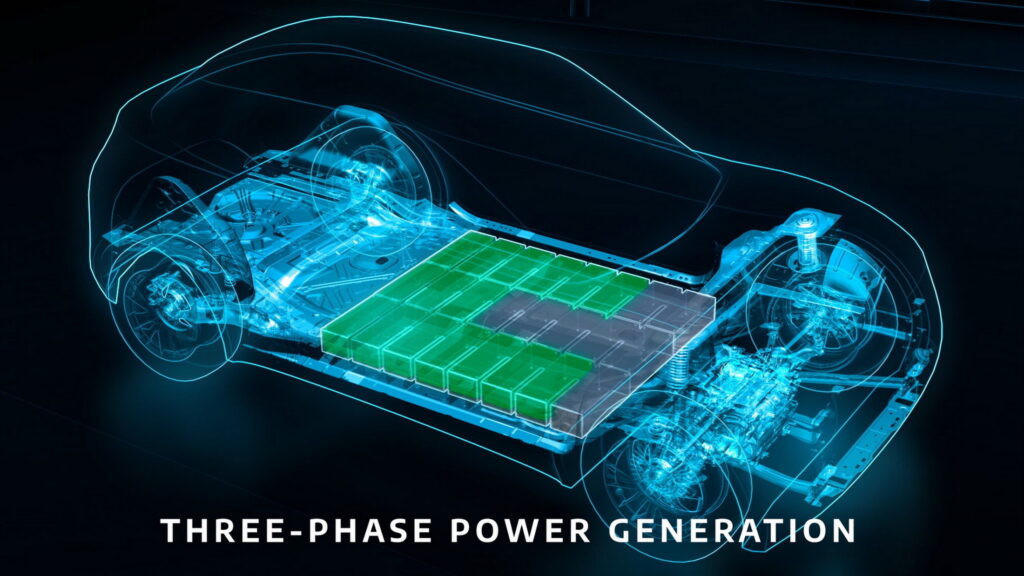

Stellantis says that IBIS’ sophisticated control system allows it to produce an alternating current that can go straight into the electric motor, without need for an inverter, meaning that it and onboard charger can be eliminated, leaving more room in the cabin for passengers, and reducing weight.

Read: Stellantis Commits $11.2 Billion To Semiconductors Through 2030

It says that the IBIS system also has the capability to reduce the cost of the EV powertrain, simplifying the manufacturing process, and (since the whole thing is lighter) it allows the vehicle to travel farther on a charge. In addition, the technology could be useful in stationary batteries, for generators and power banks.

“Our journey to electrification is fueled by innovation and research excellence that uses the latest technology to address the real needs of our EV customers such as range, roominess and affordability while reducing carbon footprint by improving efficiency,” said Ned Curic, Stellantis Chief Engineering & Technology Officer. “This revolutionary battery system could mark a decisive step in Stellantis’ commitment to provide useful, easy and advanced technology to all.”

Stellantis says that it is working to have the technology for its production before the end of the decade. Now that the technology has been bench tested, the next step on that journey will be to build a fully functional prototype vehicle that can be tested and developed on its test tracks and the open road.